The development of an ability to "see at night" has been the subject

of research and development for

many decades. Night vision is usually achieved by using staring infrared

focal plane detector arrays.

Infrared focal plane arrays have both commercial and defense applications.

Some examples of

commercial applications include: visual aids for automobile drivers

so that they can see beyond

oncoming headlight glare and well beyond the normal range of the vehicle

headlights; visual aids for

commercial aviation for use in conditions of reduced visibility; monitoring

industrial machines and

processes for proper operation temperature with non-contact IR-imaging;

and thermal imaging in

medicine (thomography). Security, fire and search and rescue services

will benefit from the

availability of low cost night vision infrared imagers. Defense applications

include: night vision, low

visibility target detection, tracking and remote earth observations.

Most infrared detectors have centered on the 3-5 mm (MWIR) and the 8-12

mm (LWIR)

wavelength bands because of the high atmospheric transmission at these

wavelengths. Detection in

the 3-5 mm range has been traditionally achieved by InSb based detectors

while the 8-12 mm range

has been covered by detectors made of HgCdTe. On the other hand, recent

emerging technologies

such as quantum well based detectors and uncooled thermal sensors using

silicon microbolometers

provide many advantages over conventional detectors. These include

the capability of multicolour

detection for identification of objects and more importantly uncooled

detectors for low cost thermal

imaging. In this article, we report some of the recent work that has

being carried out on multicolour

detectors and silicon based uncooled microbolometers.

Bolometer infrared sensors operate by converting the incident infrared

radiation into a temperature

rise of its supporting membrane. This temperature rise causes the resistance

of a resistive sensing

element attached to the membrane, to change by an amount proportional

to the incident infrared

power. To increase the sensitivity of detection, it is necessary to

miniaturize the bolometer and

improve its isolation from the substrate. This is usually done by silicon

micromachining which reduces

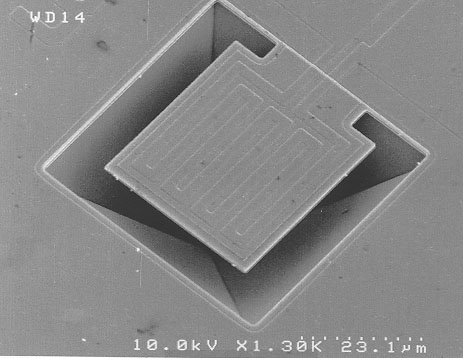

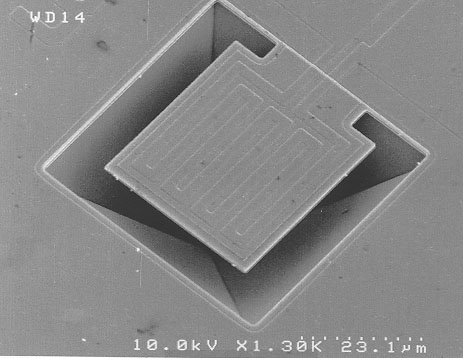

the thermal conductance between the sensor and the substrate. Figure

1 shows a silicon

microbolometer fabricated using micromachining. This work was performed

in collaboration with the

Institute of Microelectronics (IME). Since the heat capacitance of

the bolometer is relatively small, it

can experience a significant temperature rise under a weak infrared

power (10 nW). By monitoring

the resistance change of the sensor, the corresponding infrared signal

can be detected. This is usually

achieved by passing a bias current through the sensor element and measuring

the resultant voltage

drop across the sensor element. Figure 2 shows the measured infrared

response of a

microbolometer at room temperature. The roll-off of the frequency response

of the sensor gives the

limit of operating speed which is determined by the thermal time constant.

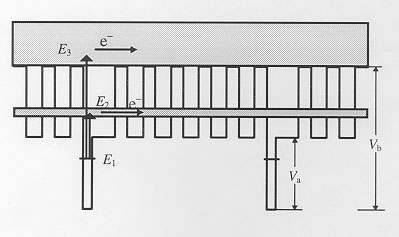

Another area of interest is the fabrication of multicolour detectors

to enhance the performance of

detection, in particular, for discrimination of objects and imaging

under varying atmospheric

conditions. To obtain a response at two wavelengths, an InGaAs/GaAs

step quantum well designed

to have three energy levels (E1, E2 and E3) as illustrated in Figure

3, was employed. The asymmetry

of the step quantum well distributes the oscillator strength between

the two transitions, E1 ® E2 and

E1 ® E3. The E1 and E2 states are bound and are located in the

step quantum well while the E3 is

positioned just above the barrier to efficiently collect the photoexcited

carriers. However, the E2

level is much lower than the barrier height which makes its harder

for the E1 ® E2 photoexcited

electrons to escape from the quantum wells. To overcome this difficulty,

we employed a 5-period

AlGaAs/GaAs superlattice barrier, with the first miniband aligned with

the E2 state in the quantum

well, as schematically shown in the Figure 3. This allows the photoexcited

electrons to move along

the miniband.

The QW multicolour detector structure used in this study was grown on

a semi-insulating (100)

GaAs substrate by molecular beam epitaxy (MBE). It has 20 periods of

step quantum wells and

superlattice barriers sandwiched between two 1 mm thick GaAs layers

doped with Si to 1´ 1018

/cm3 for ohmic contacts. The step quantum well consists of a 30 Å

thick In0.3Ga0.7As well doped

with Si to 1´ 1018 /cm3 and a 73 Å thick undoped GaAs step.

The thickness of the InGaAs layer in

the step quantum well was kept below the critical thickness corresponding

to the 30% in

composition. The superlattice barrier that separates the step quantum

wells consists of undoped

5-periods of 51 Å thick GaAs wells and 40 Å thick Al0.26Ga0.74As

barriers. For the infrared

response measurement, diodes of 200 mm ´ 200 mm were fabricated

using standard

microelectronics processing techniques.

The spectral dependence of the photoresponse was measured using a ceramic

infrared source

coupled to an Oriel MS257 grating monochromator with lock-in detection.

Figure 4 shows the

responsivity (mA/W) as a function of the incident photon energy for

several bias voltages at 60 K.

The photon flux as a function of wavelength was measured simultaneously

using a calibrated

pyroelectric detector. There are two peaks of the photoresponse at

about 110 meV and 220 meV

corresponding to the E1 ® E2 and E1 ® E3 transitions, respectively.

Source: Engineering Research News, National University of Singapore,

Feburary 1998